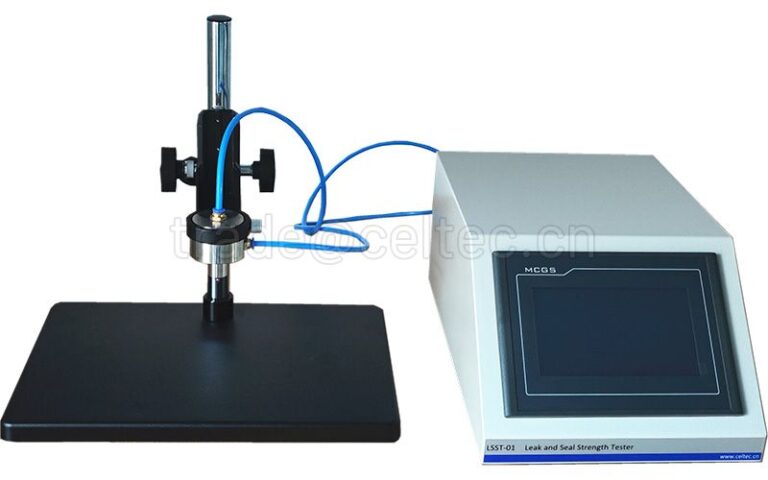

1.Introduction of LSST-01 Leak and Seal Strength Tester|、Plastics Testing

The LSST-01 Tester for lekkasje- og tetningsstyrke is designed for the evaluation of seal performance and integrity in a wide range of packaging materials. Utilizing the highly effective pressure decay method, LSST-01 subjects the sample to pressurization up to predefined levels. The subsequent measurement of any decrease in pressure acts as a precise indicator, revealing potential leaks.

Our burst Tester|、Plastics Testing factory for pouches, also known as a pouch burst tester, is essential for evaluating the burst strength of packaging materials. The burst test machine for pouches ensures precise measurements, making it ideal for pouch burst tests. Our pouch burst test equipment is designed to facilitate thorough pouch burst test preparation, ensuring reliable and accurate results.

2.Advantages of LSST-01 Leak and Seal Strength Tester

Pressure Decay Method: The LSST-01 uses the pressure decay method. It pressurizes the sample to a specific level and the embedded the pressure sensor monitors the decrease in pressure. This helps to identify possible leaks clearly and accurately.

Versatile Applications: LSST-01 is versatile, offering the quantitative determination of various critical parameters, including seal performance, seal quality, burst pressure, compression resistance, torsion force, and joint/disengaging force. Its applicability extends to a diverse range of packaging materials, encompassing flexible packages, aseptic packages, plastic pilfer-proof closures, flexible tubes, caps, and more. (Different sample form may need different jigs).

Precision and Accuracy: With the PLC control embedded, HMI screen and pressure sensor, the LSST-01 is precise in assessing how well different packaging materials seal.

User-Friendly Design: By professional design of gas regulating, sample placing, control and display, the LSST-01 is simple to use.

3.Why do you need LSST-01 Leak and Seal Strength Tester?

●LSST-01 Leak and Seal Strength Tester is commonly known as a destructive method, particularly suitable for evaluating empty packages or containers.

●This tester offers three test modes: burst test, creep test, and creep to failure test, enabling a comprehensive analysis of sample performance under controlled pressure conditions.

●The LSST-01’s adaptability is a key feature, achieved through the development of a range of sample jigs tailored for various applications and materials.

●We can realize restrained and unrestrained test described in ASTM F1140 and ASTM F2054. By modification, LSST-01 can also comply with ASTM F2096.

4.Technical Features

●LSST-01 Leak and Seal Strength Tester is controlled by PLC, ensuring industrial-level stability, and featuring a user-friendly 7-inch HMI touch screen for operation.

●Real time display and automatic recording of test results.

●Compatibility with various fixtures designed for testing different sample forms, such as open packages (three-side-seal), closed packages, doy packs, tubes, sealed trays, and cups, restraining plates, and more.

●Three available test modes: burst, creep, and creep to failure.

●User can set his own pressure sensitivity and threshold value for test.

●Pressure range extending up to 600KPa and customizable according to specific needs.

●Program can be customized for customization, meeting unique testing requirements.

5.What are the test methods of LSST-01 Leak and Seal Strength Tester?

①Burst Test

The burst test is to pressurize the package by feeding air into the package until it is failure. The test measure is the max pressure detected before failure.

②Creep Test

The creep test is to pressurize the package by feeding air into the package to specified pressure (is 70% or 80% of pressure for max burst pressure generally or set as per requirement) and maintain the inner pressure for a specific time (15~30s generally). The test measure is pass or failure.

③Creep to Failure Test

The creep to failure is similar with creep, but during pressure maintaining the package is failure. The pressure inside is 90% of pressure (or set as per requirement) for max burst pressure generally. The test measure is the time until the package is failure.

6.Application:

Den LSST-01 Leak and Seal Strength Tester is your tool for ensuring packaging reliability. Using the pressure decay method, it accurately checks for potential leaks by pressurizing samples. Versatile and user-friendly, it works for seal performance and burst pressure test of various types of materials. With easy PLC control and customizable options, the LSST-01 simplifies testing while ensuring accuracy. Choose LSST-01 for straightforward, effective testing that ensures your packages stay intact and secure.

7.Specifications

| Model | LSST-01 |

| Test Range | 0 ~ 600Kpa(standard) |

| Probe Size | Φ4mm (standard, Closed Pack Jig) |

| Beam Width | 320mm (Open Pack Jig) |

| Control | PLC, HMI Touch Screen |

| Gas Inlet | Φ6 mm PU hose |

| Power | Single Phrase, 110V~220V, 50Hz |

| Compressed Air | 0.7Mpa (Prepared by User) |

| Working Temperature | Room Temperature |

8.Standards:

ASTM F1140, ASTM F2054, ISO 11603-1, ISO 11603-2

9.Configuration:

Standard configuration: LSST-01 Leak and Seal Strength Tester control unit, Open Pack Jig or Closed Pack Jig, air pipe, fuses, manual, calibration certificate, power cord.

Optional configuration: Non-Standard jig, embedded or independent micro printer, RS 232 Port, COM Line, Software, air compressor

Deliveries of LSST-01

10.FAQs

Q1: What is the LSST-01 Leak and Seal Strength Tester used for?

A1: The LSST-01 is designed for evaluating the seal performance and integrity of various packaging materials using the pressure decay method.

Q2: How does the pressure decay method work in the LSST-01?

A2: The pressure decay method involves pressurizing the sample to predetermined levels and then meticulously detecting any decrease in pressure, providing a precise indicator of potential leaks.

Q3: What packaging materials can be tested with the LSST-01?

A3: The LSST-01 is versatile, accommodating flexible packages, aseptic packages, plastic pilfer-proof closures, tubes, caps, and more.

Q4: What standards does the LSST-01 comply with?

A4: The LSST-01 complies with industry standards such as ISO 11607-1, ISO 11607-2, ASTM F1140, ASTM F2054, ensuring accurate and reliable testing.

Q5: What are the advantages of using the LSST-01?

A5: The advantages include the pressure decay method for clear leak identification, versatile applications, precision and accuracy with PLC control, and user-friendly design.

Q6: Can the LSST-01 be used for non-destructive testing?

A6: Normally, the LSST-01 is commonly known as a destructive method, suitable for evaluating empty packages or containers.

Q7: What test modes does the LSST-01 offer?

A7: The LSST-01 offers three test modes: burst test, creep test, and creep to failure test, providing a comprehensive analysis of sample performance.

Q8: How is the LSST-01 adaptable to different materials?

A8: The LSST-01’s adaptability is achieved through the development of various sample jigs tailored for different applications and materials.

Q9: What customization options are available on LSST-01 Leak and Seal Strength Tester?

A9: The customization of LSST-01 includes but not limited to, the pressure reading range, air inflating probe size, width of open pack jig, displaying units, sample jigs, touch screen program, software, etc.

Q10: What are the test modes offered by the LSST-01?

A10: The LSST-01 offers burst test, creep test, and creep to failure test modes, each serving a unique purpose in assessing packaging integrity.

Q11: How does the LSST-01 contribute to compliance with industry standards like ASTM F1140 and ASTM F2054?

A11: The LSST-01 can perform restrained and unrestrained tests as described in ASTM F1140 and ASTM F2054, ensuring adherence to industry standards.

Q12: What type of real-time feedback does the LSST-01 provide during testing?

A12: The LSST-01 features a user-friendly 7-inch HMI touch screen that provides real-time display and automatic recording of test results for easy monitoring.

Q13: How user-friendly is the LSST-01 in terms of operation and control?

A13: The LSST-01 is designed for user convenience with PLC control, a touch screen interface, and easy gas regulation, ensuring simple and efficient operation.

Q14: Can the LSST-01 handle different sample forms?

A14: Yes, the LSST-01 is compatible with various fixtures designed for testing different sample forms, including open packages, closed packages, doy packs, tubes, sealed trays, and cups.

Additionally, our leak and seal strength tester assesses both leak and seal strength, serving as a comprehensive leak and seal strength detector. This equipment is crucial for maintaining the integrity and quality of pouches in various applications.

Hvis du ønsker mer informasjon om dette produktet, er du velkommen til å kontakte oss. Anbefaler andre populære produkter for deg: Gradient Heat Seal Tester Produsent, Heat Gradient Tester, testing av plastfilm, Containertester, Gradient Heat Seal Tester, Laboratory Heat Seal Tester, ampoule break force test, agar gel strength test, china heat seal tester factory, china heat seal tester suppliers, china heat sealing tester, varmeforseglingstester fabrikker, varmeforseglingstester fabrikk, varmeforseglingstester pris, varmeforsegling tester fabrikker, varmeforseglingstester fabrikk, Varmeforseglingstester fabrikk, Paper Board Tester wholesaler, Plastic Film Tester factory, Gradient Heat Seal Tester factory, Gradient Heat Seal Tester wholesaler, Gradient Heat Seal Tester China, Plastic Film Testing factory, china heat sealing tester factory