1.Introduction of Falling Ball Impact Tester

Falling Ball Impact Tester measures the resistance performance of plates, sheets, and composites, films foils, paper etc. with less than 2mm thickness. By impact test, the material ability to resist external destruction can be indicated.

User observes the destruction status of the test specimen after it has been hit by a falling weight that fell from a given testing height.

By modification and extra jigs, Falling Ball Impact Tester can also be used to assess the impact resistance of various other products, including goggles, helmets, face shields, bottle caps, and more.

Uses

Evaluation of impact resistance: Mainly used to evaluate the material’s resistance to sudden impact, especially its durability and reliability during transportation and handling.

Quality control: Ensure that materials meet industry standards and customer requirements, and reduce product losses caused by material damage.

Product development: Help researchers and engineers select appropriate materials, optimize product design and packaging solutions, and ensure the overall quality and performance of the product.

2.Advantages of Falling Ball Impact Tester

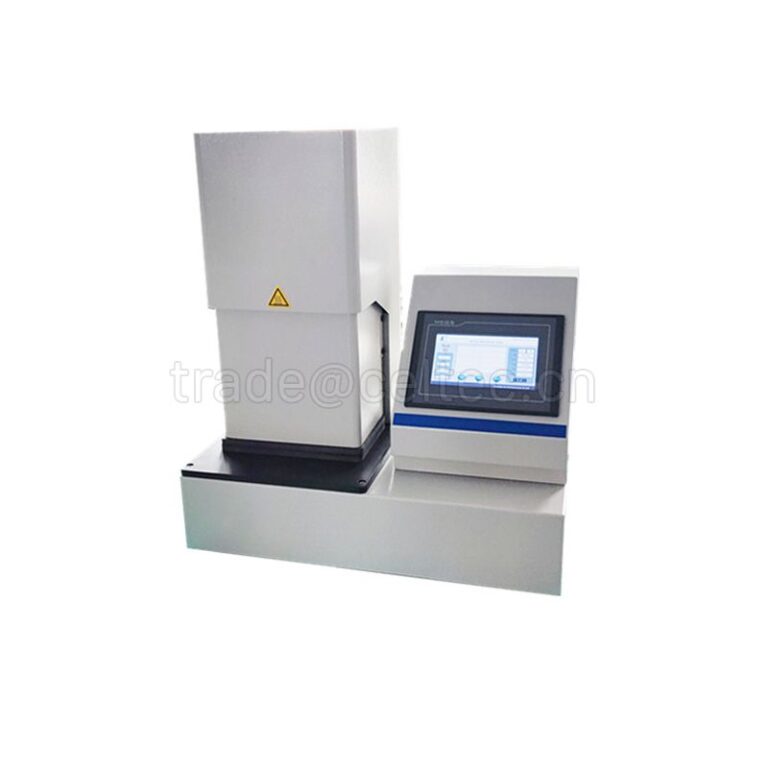

Spletna stran Falling Ball Impact Tester is a system with PLC control (maintaining industrial-grade stability) and is operated via an HMI touch screen interface. Key Features:

1. Precision PLC control and user-friendly touch screen interface

2. Adjustable impact height with a variety of available ball options

3. Display of test results in multiple units

4. Utilizes electromagnetic suspension for automatic ball release

5. Secure sample clamping through pneumatic mechanisms

6. Convenient manual and foot switch operation

7. Equipped with a dot matrix micro-printer

8. Option for advanced professional software (available as an add-on)

3.Test Principle

A steel ball of known mass and diameter is released from a predetermined height, creating a controlled impact force on the test sample. The impact energy and the resulting damage or deformation are measured and analyzed to assess the material’s impact resistance.

4.Application of Dropping Ball Impact Tester:

Falling Ball Impact Tester can be used for plastic films, sheets, Protective Eyewear (Goggles), Helmets, Face Shields, Bottle Caps

5.Specifications of Dropping Ball Impact Tester

| Impact Height | 300mm-600mm (can be extended) |

| Ball Diameters (mm) | 23, 25, 28.6, 38.1, 50.8(one equipped) |

| Accuracy | 0.1g (0.1J) |

| Specimen Clamp | Pneumatic Clamp |

| Gas Supply | 0.6 MPa Φ8 mm PU Pipe |

| Specimen Size | > 150 mm x 150 mm |

| Power Supply | AC 110~220V 50Hz |

6.Standards:

GB/T 15267, GB/T 17876, GB/T 14485, YBB00202005, YBB00212005, YBB00222005, YBB00232005

7.Configuration:

a)Standard configuration: Falling Ball Impact Tester, steel ball, fuses, manual, calibration certificate, power cord.

b)Optional configuration: Non-Standard steel balls, RS 232 Port, COM Line, Software, air compressor

8.FAQs

1. What are the factors that influence the test result in ball impact testing?

The two factors influence ball impact test result are drop height and ball size and mass.

2. What does the Falling Ball Impact Tester measure?

It measures the resistance performance of materials with less than 2mm thickness through impact testing.

3. Can the FBT-01 assess impact resistance for products other than films and sheets?

Yes, with modification and extra jigs, it can evaluate goggles, helmets, face shields, bottle caps, and more.

4. How does the FBT-01 Falling Ball Impact Tester work?

It releases a steel ball from a predetermined height to create a controlled impact force, assessing material resistance based on resulting damage.

5. Which standards does the FBT-01 Falling Ball Impact Tester comply with?

GB/T 15267, GB/T 17876, GB/T 14485, YBB00202005, YBB00212005, YBB00222005, YBB00232005.

Če želite več informacij o tem izdelku, se obrnite na nas. Priporočamo vam tudi druge priljubljene izdelke: Pendulum Hammer Striking Tester