Introduction

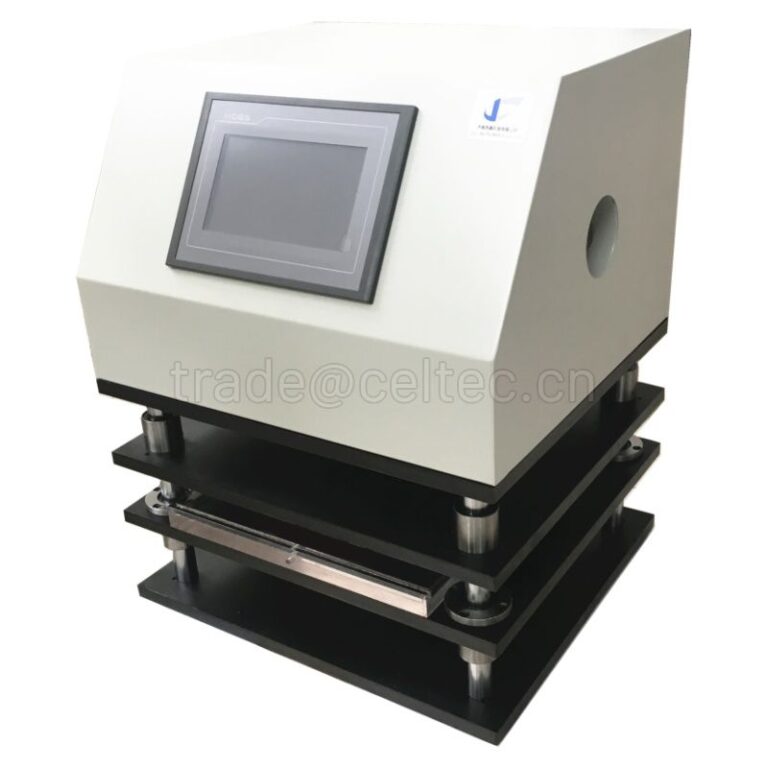

Το Package Compression Tester (PCT-01) is an advanced instrument designed to evaluate the compression strength and durability of various packaging materials. This critical testing device is essential for industries like food, pharmaceuticals, medical devices, and cosmetics, where packaging integrity is paramount for product safety and customer satisfaction. By accurately measuring a package’s resistance to compressive forces, the PCT-01 ensures that packaging materials meet high standards of durability and performance, helping manufacturers protect products throughout the supply chain.

Application of the Package Compression Tester

Το PCT-01 Package Compression Tester is versatile and designed for pressure resistance measurement across a range of packaging types, including:

- Composite films for flexible packaging

- Paper cups, bowls, and containers for food service and retail

- Medical packaging, including infusion bags, plastic infusion bottles, and blood bags

- Specialty items like ice bags and pharmaceutical pouches

This tester is particularly valuable in assessing the strength of packaging used in high-risk environments, from food storage to medical supply transport, providing reliable data for quality assurance and regulatory compliance.

Working Principle

Το Package Compression Tester operates on a straightforward principle, replicating the conditions that packaging may experience during stacking, handling, and transport:

- Placement of the Sample: The sample is placed between the upper and lower pressure plates, ensuring secure positioning.

- Compression Process: The upper plate moves downward to apply force on the sample, simulating external pressures it would encounter in the real world.

- Force Measurement: The lower pressure plate measures the force exerted on the sample in real time, capturing critical data about the sample’s bursting strength και constant pressure resistance. This process allows manufacturers to understand how materials and designs perform under stress, ensuring packages withstand various environmental conditions.

Key Features of the PCT-01

Το PCT-01 Package Compression Tester boasts a range of features that enhance its precision, versatility, and ease of use:

- User-friendly HMI touch screen for easy parameter setting and test operation

- Σύστημα ελέγχου PLC βιομηχανικού επιπέδου for reliable testing and data accuracy

- Dual test modes: measures both maximum bursting force και constant pressure resistance

- Automatic constant pressure compensation adjustment, ensuring accurate results in varying conditions

- Data statistics functionality to record and manage test results seamlessly

- Integrated liquid collection device to prevent contamination in the event of a sample rupture

- Customizable testing sizes for non-standard samples

- RS232 port and optional software compatibility, allowing for data analysis and storage

These features make the PCT-01 ideal for a wide range of testing applications, offering both flexibility and precision in analyzing packaging performance.

Testing Procedure and Compression Strength Test

Το compression strength test on the PCT-01 follows a straightforward procedure designed for reliability and efficiency:

- Sample Preparation and Placement: Position the sample securely between the upper and lower plates.

- Setting Parameters: Use the intuitive touch screen to configure test parameters, such as time, force range, and measurement units.

- Initiate the Test: The upper plate applies compressive force on the sample. Real-time force measurement data is displayed and recorded.

- Result Interpretation: After the test, the data can be analyzed to understand the sample’s compression strength and determine its suitability for specific applications.

Technical Specifications

Το Package Compression Tester offers high measurement accuracy and customizable features to fit diverse testing needs:

| Measuring range | 2000N (other optional) |

| Measurement accuracy | 0.50% |

| Time range | 0~10000S |

| Platen size | 250mm*300mm (can be customized) |

| Power supply | 220V, 50HZ |

| Dimension | 460mm*410mm*590mm |

Benefits of Using the Package Compression Tester

For manufacturers, using the PCT-01 brings several benefits that help ensure the quality and safety of packaged goods:

- Enhanced Product Protection: Regular testing prevents packaging failure, safeguarding products from damage.

- Consistency in Quality: Detailed, repeatable data helps maintain high standards in packaging materials.

- Compliance with Industry Standards: The PCT-01 supports quality control protocols necessary for regulatory compliance.

- Reduced Costs: Identifying issues early can prevent costly product returns, damages, and recalls, leading to long-term savings.

- Improved Customer Satisfaction: Reliable packaging builds trust with consumers, enhancing brand reputation.

FAQs About the Package Compression Tester

Q1: What types of packaging materials can the tester handle?

- A: The PCT-01 can test a wide variety of packaging, including composite films, paper containers, medical bags, and more.

Q2: How does the package compression tester measure compression strength?

- A: The lower plate measures the applied force in real time, determining the material’s strength and resistance.

Q3: Can the tester be customized for unique packaging sizes?

- A: Yes, it offers customization options for non-standard test sizes to accommodate various packaging requirements.

Q4: What data output options are available?

- A: Test data can be exported via the RS232 port and optional software for detailed analysis and record-keeping.

Q5: How does the liquid collection device work?

- A: The liquid collection device captures any released liquids in the event of a rupture, preventing contamination and maintaining a clean testing environment.