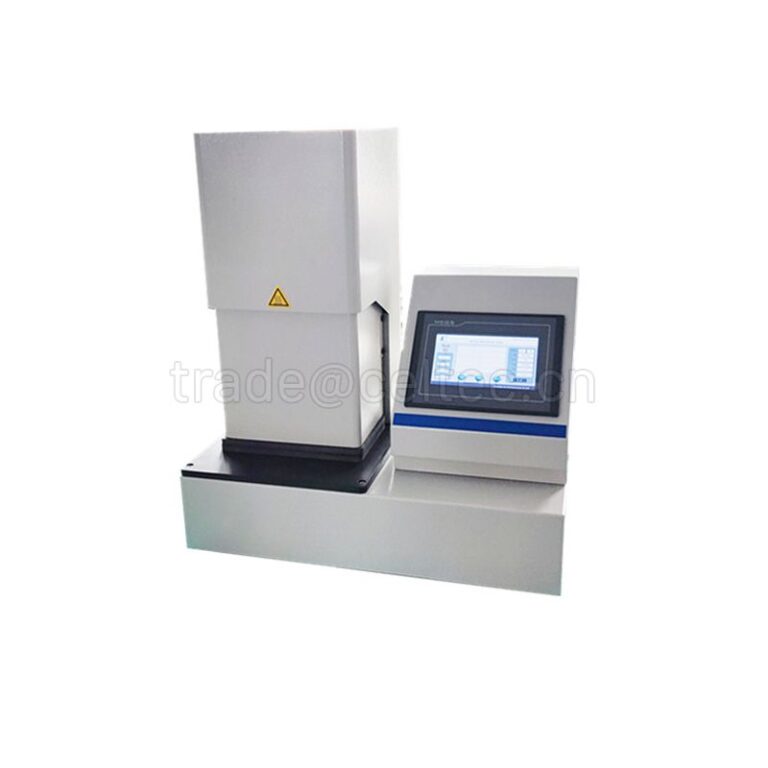

1.Introduction of FSR-01 Shrink Force and Ratio اختبار | | اختبار البلاستيك

The FSR-01 Shrink Force and Ratio Tester serves the purpose of measuring both the shrinking forces and shrinkage ratio of heat shrinkable films. These films are typically created through extrusion and stretching (hot drawing) during their manufacturing process, retaining this stretched state even after cooling.

Shrinkage is determined by immersing the film in an oil bath at a selected temperature. The shrinkage in the machine and transverse directions is determined as a function of time.

The shrinkage tension determination is based on DIN 53369. The test specimen is connected to a load cell, briefly placed in a hot oven and then cooled to room temperature. The forces generated during the shrinkage of the material are recorded.

Shrink films are used as outer packaging for a wide variety of packaging. When heat is applied to the film, it shrinks and wraps tightly around the covered object. The shrinkage of the film is based on the relaxation of the orientation stresses introduced during the film production process. Stress relaxation allows for a good closure of the package.

2.Why do you need a Shrink Force and Ratio Tester|、Plastics Testing factory?

When the heat shrinkable film is reheated to the temperature at which the initial stress was introduced and subsequently fixed during its production, this stress is released, causing the film to contract or “shrink back.” Depending on the specific manufacturing treatment applied, the film can be categorized as either biaxially oriented (stretched in two directions) or uniaxially oriented (stretched in one direction).

3.Technical features of FSR-01 Shrink Force and Ratio Tester|、Plastics Testing export

1. PLC Control and HMI Touch Screen: ensuring industrial-level stability.

2. Well-Insulated Air Oven: The air oven is excellently insulated and capable of automatic lowering and lifting, enhancing the precision of the testing.

3. Non-Contact Shrink Ratio Measurement: accomplished through a noncontact method, improving accuracy and reliability.

4. Real-Time Display: including shrinking force, contracting force, and shrinkage ratio, allowing for immediate analysis and monitoring.

5. Elimination of Interference Factors: Irrelevant interference factors like friction and cool air are effectively eliminated, ensuring the accuracy of the results.

6. Stable Heating System: The heating system is stable and well-balanced, maintaining consistent and controlled test conditions.

7. Easy Sample Loading: Sample loading is made easy, streamlining the testing process and reducing setup time.

8. High-Resolution Sensors: The system is equipped with high-resolution force transducers and thermometers, guaranteeing precise measurements.

9. Connectivity and Software:(optional) It includes an RS232 port for data connectivity and offers optional professional software for advanced data analysis and reporting capabilities.

4.Test Principle

1. A well-insulated air oven is heated to the set temperature. The two samples are placed separately on two test stations, for shrinkage rate and shrink/contraction force testing.

2. A temperature probe is located to measuring area, to give result as reference temp. The air oven is driven down automatically to cover the sample area. The force and shrink rate are to be measured and the shrinkage temperature is reached when the maximum shrinking force is attained.

3. When this force has decreased by around 15%~30%, the air oven is lifted and time is recorded.

4. The assessment of shrinkage ratio is performed at the mean time

5- المواصفات

| نطاق القوة | 5 N (or as required) |

| الدقة | ±0.5% |

| Resolution | 0.001N |

| Displacement Range | 0.1 ~ 95 mm |

| الدقة | ±0.1 mm |

| Temperature Range | Ambient ~ 210°C |

| الدقة | ±0.5°C |

| No. of Specimens | 2 |

| Sample size | 110*15 mm, L*W |

| مزود الطاقة | 220V 50Hz |

6-المعايير:

ISO 14616, DIN 53369, GB/T 34848

- ISO 14616 – Plastics — Heatshrinkable films of polyethylene, ethylene copolymers and their mixtures — Determination of shrinkage stress and contraction stress

- DIN 53369 – Testing of plastic films — determination of the shrinking stress

- GB/T 34848 – a national standard on performance test methods for heat exchangers and heat transfer elements. It is mainly used to regulate and guide the performance testing and evaluation of heat exchange equipment and its components during design, manufacturing and use.

7.التكوين:

a)Standard configuration: FSR-01 Shrink Force and Ratio Tester, fuses, manual, calibration certificate, power cord.

b)Optional configuration: Non-Standard jaws, RS 232 Port, COM Line, Software, air compressor

For more information about our products, please contact us!

8.الأسئلة الشائعة

1. What is the purpose of the FSR-01 Shrink Force and Ratio Tester?

– FSR-01 Shrink Force and Ratio Tester is used to measure shrinking Force, Contracting Force and Shrinkage Ratio of heatshrinkable film.

2. Why is it necessary to use a Shrink Force and Ratio Tester for heat shrinkable films?

– The tester helps evaluate the film’s behavior when reheated to the temperature at which the initial stress was introduced during production, allowing precise measurement of both shrinking forces and shrinkage ratios based on specific manufacturing treatments.

3. What are the technical features that make the FSR-01 Shrink Force and Ratio Tester reliable?

– Key features include PLC control and HMI touch screen for industrial-level stability, well-insulated air oven with automatic lowering and lifting, non-contact shrink ratio measurement for improved accuracy, real-time display of shrinking force and ratio, elimination of interference factors, stable heating system, easy sample loading, high-resolution sensors, and optional connectivity with professional software.

4. How does the FSR-01 perform the shrink force and ratio testing?

– The air oven is heated to the set temperature, and two samples are placed on separate test stations for shrinkage rate and shrink/contraction force testing. The force and shrink rate are measured, reaching the shrinkage temperature when the maximum force is attained. The assessment of shrinkage ratio is performed when the force decreases by around 15%~30%.

إذا كنت ترغب في الحصول على مزيد من المعلومات حول هذا المنتج، فلا تتردد في الاتصال بنا. نوصي بمنتجات شائعة أخرى لك: Hot Air Thermal Shrinkage Tester, Thermal Shrinkage Tester, Heat Shrinkage Testing Machine, film free shrink tester, جهاز اختبار الانكماش الحراري الغشائي, اختبار الأغشية البلاستيكية, thermal shrinkage tester, Plastic Film Tester factory, Shrink Force and Ratio Tester supplier, Shrink Force and Ratio Tester solution, Plastic Film Testing factory, Plastic Film Tester export, Ampoule Breaking Tester export, Film Free Shrink Tester wholesaler