1. Introduction

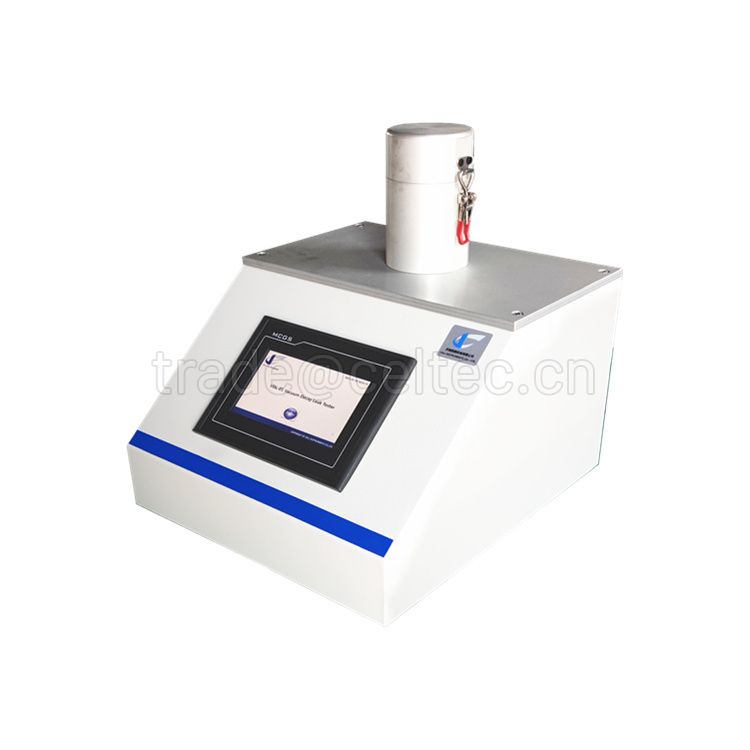

Micro Leak Testing Machine adapts the vacuum decay method and is used to detect package leaks by measuring the rise in pressure (vacuum loss) in an enclosed evacuated test chamber containing the test package. Vacuum loss results from leakage of test package headspace gases and/or volatilization of test package liquid contents located in or near the leak. It is widely used in integrity test of vials, ampoules, prefilled needles, infusion bottles/bags, etc.

Micro Leak Testing Machine is a vacuum decay leak tester that can evaluate the performance of sealed packaging. It’s a non-destructive testing method that can be used to test the sealing performance of pharmaceutical packaging without damaging the sample.Micro Leak Testing Machine follows ASTM F2338 standards and is useful in micro leaks in packaging for industries like food. It can identify micron holes and leaks in glass or plastic containers filled with powder or liquid.

Our vacuum decay leak tester is essential for detecting leaks in various products, following the ASTM vacuum decay leak test method. Understanding vacuum decay leak testing is crucial, and our equipment provides a reliable vacuum decay leak testing procedure, ensuring precise results. Our vacuum decay leak test equipment is designed to perform micro leak testing with high sensitivity, accurately identifying even the smallest leaks.

2. Benefits

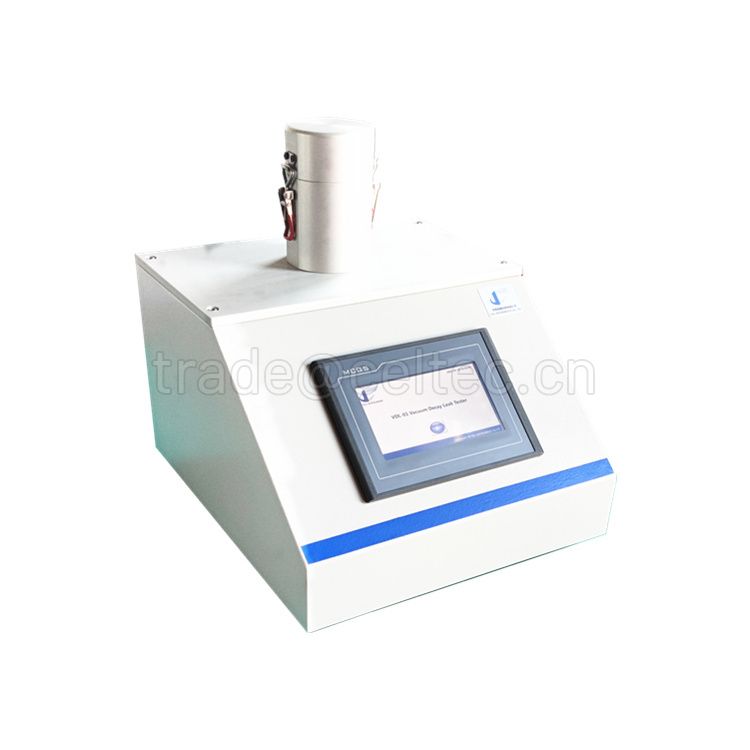

PLC controlled and HMI human-machine interface operated

Tailored chamber size

High sensitivity for detecting minute leaks.

Non-destructive leak testing method

Calculates a leak rate effectively

Dual Sensor Method of absolute pressure sensor and differential pressure

3. Application

Rigid and semi-rigid non-lidded trays.

Trays or cups sealed with porous barrier lidding material.

Rigid, nonporous packages.

Flexible, nonporous packages.

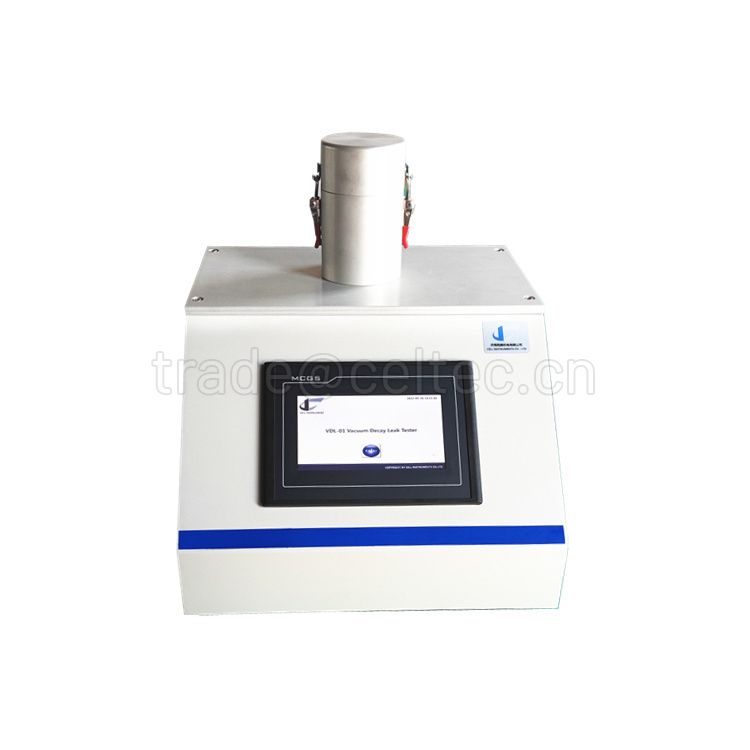

4. Specifications

| Absolute pressure test range | (0~300) kPa |

| Differential pressure test range | (-2~2) kPa |

| Detection sensitivity | 1~2μm |

| Balance/Test time | 1~3600 s |

| Vacuum time | 1~3600 s |

| Set flow rate | 0~3 mL/min |

| Test system | Dual Sensor Method of absolute pressure sensor and differential pressure |

| Test chamber | Made on Demand |

| Power | AC 110~220V, 50HZ |

5. Standards

ASTM F2338, YY/T0681.18, USP<1207.2>

Whether you are conducting vacuum decay leak testing for quality control or product reliability, our advanced vacuum decay leak testing principle and procedure guarantee comprehensive and accurate leak detection. If you have purchase needs, please contact us ir Cell Instruments will give you satisfactory products.

Jei norite gauti daugiau informacijos apie šį gaminį, nedvejodami susisiekite su mumis. Rekomenduojame jums kitus populiarius produktus: Container Tester