Introduzione

In the pharmaceutical industry, packaging integrity is a top priority. The pharmaceutical elastomeric closures penetrability test serves a crucial role in safeguarding drug quality by verifying that closures, like vial stoppers and syringe seals, remain effective even after needle puncture. This article explores the importance of this test, the standards set by ISO 8871-5, and best practices for conducting needle penetration testing.

Why the Pharmaceutical Elastomeric Closures Penetrability Test Matters

Pharmaceutical elastomeric closures are essential for preventing contamination and maintaining sterility. The penetrability test is specifically designed to evaluate whether these closures can withstand needle puncture while preserving an intact barrier.

Key Benefits of Penetrability Testing

- Protects Drug Quality: Ensures that closures maintain a sterile environment even after repeated punctures.

- Supports Multi-Dose Containers: Critical for products where the closure is punctured multiple times, such as in multi-dose vials.

- Conformità normativa: Helps pharmaceutical companies comply with standards and maintain consistent product quality.

Il pharmaceutical elastomeric closures penetrability test is thus essential for upholding safety and compliance within the industry.

Understanding Needle Penetration Testing and ISO 8871-5 Standards

A reliable needle penetration testing process is necessary to evaluate closures used in drug packaging. ISO 8871-5 provides guidelines for testing elastomeric parts used in pharmaceutical applications, including closure penetrability under specific conditions.

Overview of ISO 8871-5 Standards for Penetrability Testing

- Puncture Force Measurement: ISO 8871-5 specifies the force needed for penetration to ensure closures meet quality requirements.

- Needle Specifications: Standardized needles are used to create consistency in puncture testing.

- Controlled Testing Conditions: Environmental factors, such as temperature and humidity, are regulated for accurate results.

By adhering to ISO 8871-5, manufacturers ensure that elastomeric closures are durable enough to maintain drug safety.

Step-by-Step Guide to Conducting a Pharmaceutical Elastomeric Closures Penetrability Test

Performing the pharmaceutical elastomeric closures penetrability test involves several steps to replicate the effects of needle puncture on packaging closures. Below is a guide to the essential steps.

Key Steps in Penetrability Testing

- Prepare the Closure Sample: Position the elastomeric closure on a stable testing platform to ensure accuracy.

- Select the Proper Needle: Choose an ISO 8871-5-compliant needle to simulate real-world puncture conditions.

- Apply a Controlled Force: The needle is inserted into the closure at a specified speed and pressure to measure puncture resistance.

- Collect Data: Monitor and record puncture force, penetration depth, and any deformation observed during the test.

Testing Variables That Affect Results

Several factors can influence test outcomes, including:

- Needle Gauge and Insertion Angle: Different needles and angles can yield varying puncture resistance.

- Material Properties of Closures: Closure thickness, elasticity, and material composition impact the penetrability.

- Environmental Factors: Temperature and humidity can alter elastomer properties, so it’s essential to maintain consistent test conditions.

Using standardized protocols ensures that the pharmaceutical elastomeric closures penetrability test delivers reliable, reproducible results.

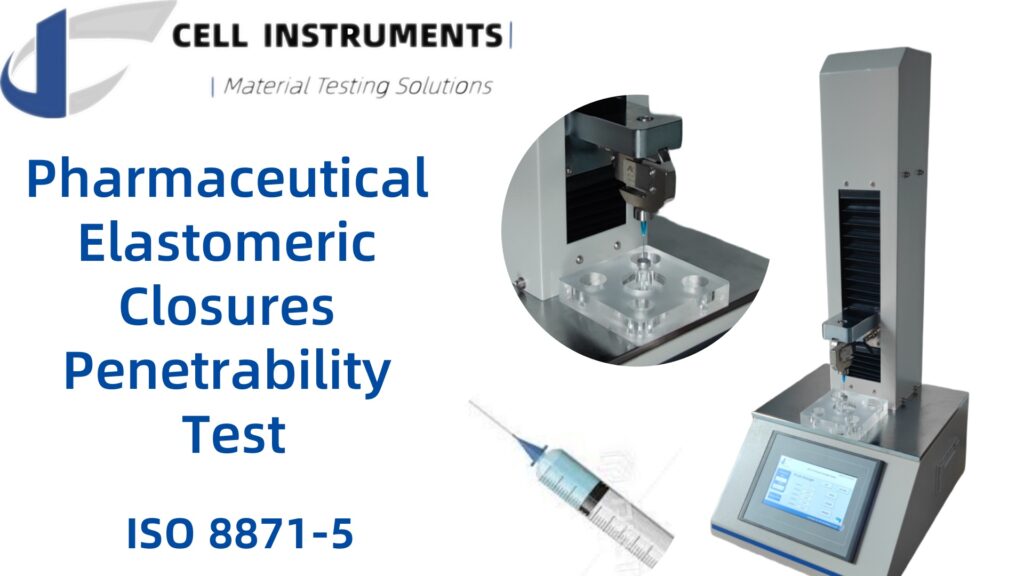

Enhancing Testing Precision with the NPT-01 Needle Puncture Tester

Il Tester di perforazione ad ago NPT-01 from Cell Instruments offers a reliable solution for performing the pharmaceutical elastomeric closures penetrability test. This equipment aligns with ISO 8871-5 requirements and delivers precision and consistency, making it ideal for pharmaceutical applications.

Key Features of the NPT-01

- Controlled Force Application: The NPT-01 ensures accurate force application to simulate realistic needle penetration.

- Wide Compatibility with Needle Types: The NPT-01 supports various needle sizes, allowing for versatile testing across different closure types.

- Automated Data Collection: Built-in data logging simplifies analysis, helping users assess closure performance quickly and accurately.

The NPT-01 enhances compliance and confidence, ensuring that elastomeric closures meet regulatory standards for puncture resistance.

Common Applications of the Pharmaceutical Elastomeric Closures Penetrability Test

The penetrability test is widely used in pharmaceutical packaging to verify the safety and durability of closures used in injectable drugs and other products.

Applications Include:

- Vial and Syringe Closures: Ensuring closures can withstand multiple punctures without compromising sterility.

- Infusion Bags and Multi-Dose Vials: Verifying the durability of closures under repeated use conditions.

- High-Value Drug Packaging: Testing closures for sensitive drugs where any contamination risk must be minimized.

Conclusione

Il pharmaceutical elastomeric closures penetrability test is fundamental to maintaining drug safety and packaging integrity. Conducting this test in alignment with ISO 8871-5 standards and using reliable equipment like the Tester di perforazione ad ago NPT-01 supports pharmaceutical companies in achieving regulatory compliance and consistent product quality.

FAQ

1. What is the purpose of the pharmaceutical elastomeric closures penetrability test?

This test verifies that elastomeric closures can maintain sterility even after multiple needle punctures, which is vital for drug safety.

2. How does ISO 8871-5 impact the penetrability test?

ISO 8871-5 provides guidelines for conducting standardized penetrability testing, helping to ensure that closures meet strict quality standards.

3. What advantages does the NPT-01 Needle Puncture Tester provide?

The NPT-01 offers precise, consistent force application, supports multiple needle types, and features automated data recording, aiding in compliance with ISO 8871-5.

4. Why is environmental control important in penetrability testing?

Factors like temperature and humidity can impact elastomer properties, so controlling these conditions is essential for accurate test results.

5. What types of closures are tested using penetrability tests?

The test is commonly applied to vial stoppers, syringe seals, and other elastomeric closures used in pharmaceutical packaging, particularly for multi-dose containers.