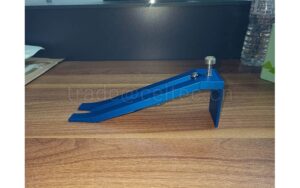

1.Introduction of BTT-01 Ball Tack Tester

BTT-01 Ball Tack Tester is for the measurement of the comparative tack of pressure-sensitive adhesives by a rolling ball. It’s an inclined trough equipped with a release lever at the top through which the ball gains downhill momentum. The ball is a 7⁄16-in. (11.1-mm) diameter steel ball.

2.Advantages of Ball Tack Test?

The rolling-ball tack test is fast, easy to run, and requires little investment in equipment and little operator training. This test is intended primarily for quality control use since it demonstrates good reproducibility within a single laboratory and ability to detect batch-to-batch variations accurately if adhesive film thickness is held constant. Rolling Ball Tack is not intended as an investigative tool since for most pressure sensitive adhesive applications rolling ball tack results do not correlate well with application tack requirements.

3.Test Principle of Ball Tack Tester

A steel ball is released at the top of an incline, allowed to accelerate down the incline and roll on to a horizontal surface covered with a pressure-sensitive adhesive. Tack is determined by measuring the distance that the ball travels across the adhesive before stopping. There are two major retarding forces applied by the adhesive to the ball: (1) the adhesion between the ball and the adhesive, often called “grab,” and (2) the “plowing effect” or energy required to push the adhesive out of the ball’s path.

4.Description of Ball Tack Test:

Il LTT-01 loop tack tester is indispensable in various industries where adhesive The adhesive side of sample is up, in line with the inclined trough. The specimen must be free of any wrinkles, creases, or splices. The end of the specimen opposite the incline shall be held to the table with tape or a weight.

Release the ball and allow it to roll to a stop on the adhesive. Measure the distance from the point where the ball initially contacts the adhesive to where the ball is in contact when it stops.

5.Specifications of Ball Tack Tester

| Trough Length | 6.5 inch |

| Incline Angle | 21.3° |

| Rolling Ball | 7/16 inch (No. 14) |

| Dimension | 210*50*80mm LWH |

| Weight | 0.5kg |

6.Standards of Ball Tack Tester:

PSTC-6, ASTM D3121, JIS Z0237, GB/T 4852.

7.Configuration:

a)Standard configuration: BTT-01 Ball Tack Tester, steel ball, manual

8.FAQs

Q: What does the word ‘Tack’ mean in adhesive industry?

A: ‘Tack’ is the property of an adhesive that enables it to form a bond of measurable strength immediately after adhesive and adherend are brought into contact under low pressure.

Q: What factors influence the rolling ball tack test results?

A: The rolling ball tack test results are often influenced by (1) adhesive film thickness, (2) bond of adhesive to backing, and (3) backing rigidity, so these factors must be carefully controlled for satisfactory comparisons.

Cell Instruments has positioned itself not only as a manufacturer of state-of-the-art testing equipment but as a strategic partner in the success of businesses across the globe. Our dedicated team, equipped with a diverse range of expertise, collaborates tirelessly to ensure that our clients receive not just products but comprehensive solutions that enhance their efficiency, product quality, and overall competitiveness. Welcome your consultation!