1.Introduction of Laboratory sigillo termico Tester|、Plastics Testing

Laboratory Heat Seal Tester is designed for laboratory use, to assess the heat seal ability of surfaces, sealant layers in films, laminates, polymers, and composites. Achieving effective seals involves three parameters: time, temperature, and pressure. Laboratory Heat Seal Tester recreates the sealing process by controlling these parameters.

For more information about Laboratory Heat Seal Tester|、Plastics Testing factory, please contact us.

2.Why do you need a heat seal tester?

To make a heat seal, the film must be melted together then allowed to cool down enough to become crystalline or solid. The three interdependent elements to heat-sealing are: Heat, Pressure and Dwell time, or we call sealing temperature, sealing pressure, and sealing time.

The optimum combinations of three factors will highly affect efficiency of sealing machine and heat seal strength.

So, a tester di tenuta termica is used first before sealing machine settings, to find best three sealing parameters.

3.Advantages of Laboratory Heat Seal Tester

●PLC Controlled and HMI Operation:

– Industrial-level stability with PLC (Programmable Logic Controller) control.

– User-friendly operation through an HMI (Human Machine Interface) touch screen.

●Aluminum Construction for Heat Retention:

– Both upper and lower components constructed from aluminum.

– Double heating of jaws minimizes heat loss during sealing to ensure consistent temperature.

●Precision Temperature Control:

– First-class P.I.D. temperature controller for precise temperature regulation.

– Efficient heating for excellent sealing outcomes.

●Accurate Timing and Synchronized Seal Initiation:

– Accurate timing mechanism for precise control over sealing duration.

– Proximity sensor enables synchronized seal initiation with jaw movement.

●Guided Sealing Bar for Uniform Pressure:

– Sealing bar guided in three directions to ensure uniform pressure during sealing.

●User Safety Features:

– Anti-scald front cover prioritizes user safety.

– Manual initiation of tests or use of a foot switch for convenience and safety.

●Customizable Seal Jaws:

– Seal jaws can be customized in terms of dimensions, shapes, and patterns.

– Provides flexibility to meet specific sealing requirements.

●Connectivity and Additional Functionalities:

– RS 232 COM Port and computer software for additional functionalities (optional).

●Sealing jaw customization available in terms of shape, surface pattern and size.

4.Test Principle of Laboratory Heat Seal Tester

Place a sample between two parallel heated sealing jaws with flat surfaces. When the required temperature reaches equilibrium, the upper seal jaw, driven by a gas cylinder, is pushed down to exert a certain pressure on the sample and remain for some time. When the preset sealing time ends, the upper sealing jaw returns to its original position and the whole heatsealability testing process finishes.

5.Application:

Laboratory Heat Seal Tester can be used for plastic films, composite plastic films, paper-plastic composites, coextruded films, films with aluminum coatings, aluminum foils, composite films with aluminum foil, and various other types.

It also be used for heat sealing test of plastic tubes, the round lid for jelly cup, tray and coffee capsules, etc.

6.Specifications

| Sealing Temp. | Ambient~300℃ |

| Deviation | ±0.2℃ |

| Sealing Time | 0.1S~9999S |

| Sealing Pressure | 0.15~0.7 MPa |

| Upper Seal Jaw Surface | 330*10 mm L*W |

| Upper Jaw Surface Shape | Flat (Standard) |

| Gas Pressure | 0.7 MPa |

| Gas Port Size | Ф6 mm |

| Power | AC 220V 50Hz |

7.Standards:

ASTM F2029, QB/T 2358, YBB 00122003

8.Configuration:

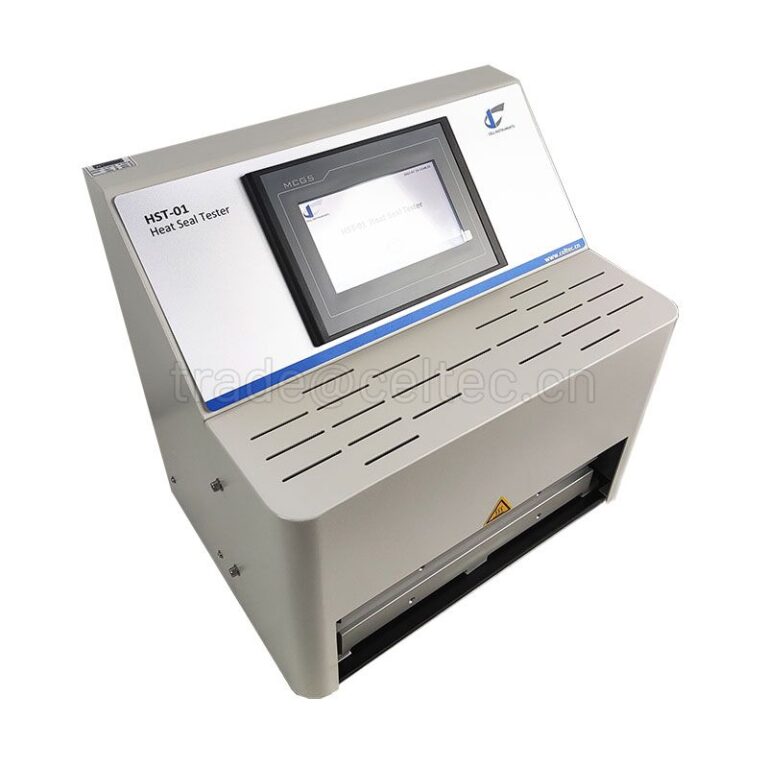

Standard configuration: HST-01 Heat Seal Tester, rubber pad, Teflon tape, fuses, manual, calibration certificate, power cord.

Optional configuration: Non-Standard jaws, RS 232 Port, COM Line, Software, air compressor

9.Deliveries of heat seal testers

10.FAQs

1. What is the purpose of the HST-01 Heat Seal Tester?

– The HST-01 Heat Seal Tester is designed for laboratory use to evaluate the heat seal ability of surfaces, sealant layers in films, laminates, polymers, and composites. It recreates the sealing process by controlling time, temperature, and pressure.

2. Why is a heat seal tester necessary?

– A heat seal tester is essential to determine the optimal combinations of sealing temperature, sealing pressure, and sealing time. These factors significantly impact the efficiency of a sealing machine and the strength of the heat seal. The tester is used to find the best parameters before configuring the sealing machine settings.

3. What are the key advantages of the HST-01 Heat Seal Tester?

– The advantages include PLC control for industrial-level stability, user-friendly operation with an HMI touch screen, aluminum construction for heat retention, precision temperature control, accurate timing with synchronized seal initiation, guided sealing bar for uniform pressure, user safety features, customizable seal jaws, and additional functionalities through connectivity.

4. What is the test principle of the HST-01 Heat Seal Tester?

– The test principle involves placing a sample between two parallel heated sealing jaws. The upper seal jaw, driven by a gas cylinder, exerts pressure on the sample for a specified time. After the preset sealing time, the upper sealing jaw returns to its original position, completing the heat sealability testing process.

5. What applications is the HST-01 Heat Seal Tester suitable for?

– The HST-01 Heat Seal Tester can be used for plastic films, composite plastic films, paper-plastic composites, coextruded films, films with aluminum coatings, aluminum foils, composite films with aluminum foil, plastic tubes, and various other materials. It is versatile and applicable for heat sealing tests on round lids for jelly cups, trays, coffee capsules, etc.

Se desiderate maggiori informazioni su questo prodotto, non esitate a contattarci. Raccomandiamo altri prodotti popolari per voi: Heat Gradient Tester, Laboratory Hot Tack Tester, plastic film testing, fabbriche di tester di tenuta termica, tester di tenuta termica in fabbrica, fabbriche di tester di saldatura a caldo, tester di termosaldatura in fabbrica, tester di adesività a caldo prezzo, Hot Tack Tester factory, Grossista di tester a caldo, Fabbrica di tester di tenuta termica, Plastic Film Tester factory, Fabbrica del tester di tenuta termica a gradiente, Gradient Heat Seal Tester wholesaler, Gradient Heat Seal Tester China, Plastic Film Testing factory, Servizi del tester di tenuta termica a gradiente