Overview

En NTT-01 Needle Toughness Tester is an advanced testing instrument designed to evaluate the bending resistance of hypodermic needles under controlled stress conditions. Following the guidelines of ISO 9626:2016, this testing system ensures that hypodermic needles maintain their integrity during the insertion and withdrawal process, critical for their safe use in medical applications. The tester offers precise control over the testing process, simulating the mechanical forces that needles experience in real-world conditions. Medical Needle Toughness Tester is suitable for measuring the toughness of human intradermal, subcutaneous, muscle and intravenous injection needle tubes and other rigid stainless steel needle tubes for medical equipment.

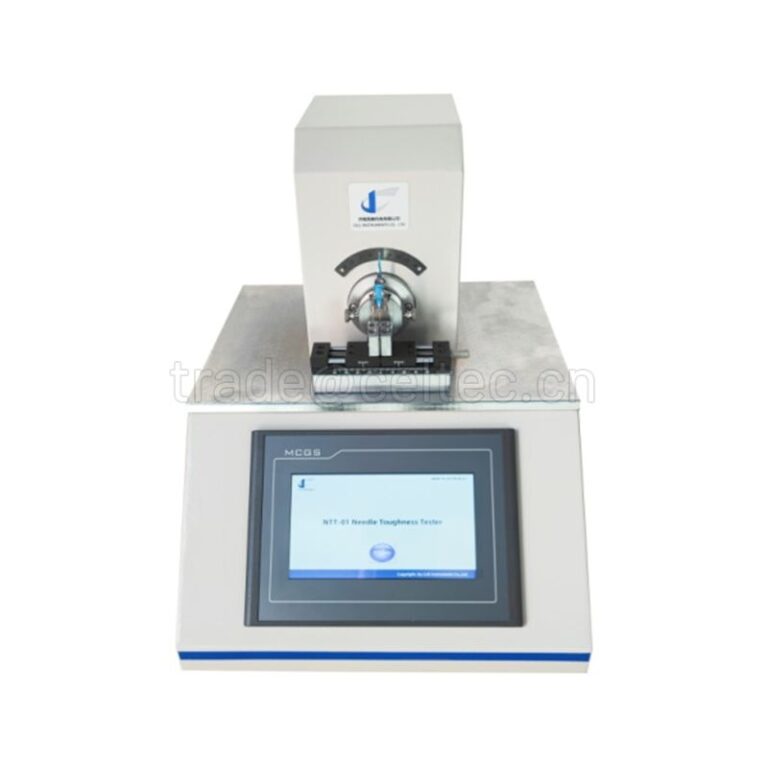

With a PLC-controlled system and an HMI touchscreen interface, the NTT-01 Needle Toughness Tester provides a seamless and user-friendly experience for conducting repeatable and accurate tests. It’s specifically engineered to determine the bending resistance of hypodermic needles, ensuring compliance with international standards and confirming the durability and reliability of medical devices.

Applications

En NTT-01 Needle Toughness Tester is indispensable for the medical device manufacturing industry, particularly in the production and quality assurance of hypodermic needles. Its primary application is in evaluating the bending resistance of needles made of various materials and wall thicknesses. The tester plays a pivotal role in the following sectors:

- Hypodermic Needle Manufacturing: Ensures needles can withstand mechanical stresses without breaking or deforming.

- Quality Control in Medical Device Testing: Vital for compliance with ISO 9626 and other international standards.

- Research and Development (R&D): Assists in developing new needle designs with enhanced durability.

- Packaging Testing: Verifies the integrity of medical packaging solutions involving needles.

By accurately simulating the forces that needles endure during insertion, withdrawal, and use, the NTT-01 Needle Toughness Tester allows manufacturers to ensure the safety and efficacy of their products.

Necessity

Hypodermic needles are exposed to significant mechanical stress during usage, both during insertion into the skin and during withdrawal. These forces can cause the needle to bend, break, or become deformed, compromising both the effectiveness of medical procedures and patient safety.

Why the NTT-01 Needle Toughness Tester is Crucial:

- Quality Assurance: It ensures that the needles meet the stringent durability requirements specified in ISO 9626.

- Safety: Reduces the risk of breakage during medical procedures, preventing potential harm to patients.

- Compliance: Ensures adherence to internationally recognized standards like ISO 9626, which governs the mechanical performance of medical needles.

Without this testing process, manufacturers cannot guarantee the performance and safety of their hypodermic needles, making the NTT-01 Needle Toughness Tester essential for quality control in medical device manufacturing.

Working Principle

En NTT-01 Needle Toughness Tester operates on a simple yet highly effective principle. The system involves securing one end of a hypodermic needle (or tubing) and applying a force at a specified distance from the fixation point to bend the needle. The bending is done in both directions (forward and reverse) to simulate the actual mechanical forces the needle would experience during usage.

- Testing Procedure: A controlled force is applied to bend the needle tubing at specific angles of 15°, 20°, or 25°, based on the wall thickness of the tubing (as per the ISO 9626 standard).

- Bending Mode: Both one-way and two-way bending modes are available for simulating different mechanical stresses that needles endure.

- Frequency and Dwell Time Control: The NTT-01 Needle Toughness Tester allows precise control of test frequency (set to 0.5 Hz) and dwell time between cycles to simulate the bending process over extended periods.

En NTT-01 Needle Toughness Tester effectively reproduces the mechanical stress that needles face in actual medical environments, offering a highly accurate test result for manufacturers to evaluate needle strength and toughness.

Technical Specifications

Main Features:

- Control System: PLC-controlled with a 7-inch HMI touchscreen for intuitive operation.

- Bending Angles: Adjustable to 15°, 20°, and 25° to accommodate different needle types.

- Test Frequency: 0.5 Hz for accurate simulation of bending cycles.

- Bending Mode: Supports both one-way y two-way bending.

- Fuente de alimentación: Operates on 110V-220V to ensure global compatibility.

Key Parameters:

- Test Angle Options: 15°, 20°, 25°.

- Frequency Control: Fixed at 0.5 Hz.

- Bending Mode: Two-way and one-way bending.

- Dwell Time: Adjustable for more precise control of bending cycles.

- Fuente de alimentación: 110-220V, ensuring it can be used worldwide.

This combination of features makes the NTT-01 Needle Toughness Tester ideal for both routine quality control checks and detailed research applications.

Advantages

En NTT-01 Needle Toughness Tester offers several distinct advantages that make it the preferred choice for testing hypodermic needles:

- High Precision: The tester ensures exact bending angles and force application, crucial for obtaining accurate and reproducible results.

- Easy Operation: With an intuitive HMI touchscreen interface, operators can easily set up tests, monitor results, and adjust parameters without the need for complex training.

- Versatile Testing: Supports multiple bending modes and angles, making it suitable for different types of hypodermic needles, including thin-walled and extra-thin-walled variants.

- Compliance with Standards: Meets the testing requirements outlined in ISO 9626 Annex C, ensuring that needles tested with the NTT-01 meet international quality standards.

- Safety: By simulating the mechanical forces needles experience, the NTT-01 Needle Toughness Tester helps manufacturers avoid potential needle breakage, reducing the risk of injury to patients.

- Reliable Results: With its PLC-controlled system y precise frequency control, the NTT-01 Needle Toughness Tester ensures accurate results with minimal error margin.

Configurations and Accessories

En NTT-01 Needle Toughness Tester comes fully equipped to meet the rigorous demands of testing:

- Needle Toughness Tester Unit: The main testing machine.

- Caliper: Used for measuring the thickness of the needles to ensure they conform to specified standards.

- Power Cord: For connecting the tester to power sources.

- Fuse: To safeguard against electrical fluctuations.

Additional accessories and configurations are available upon request to suit specific testing needs.

Normas

En NTT-01 Needle Toughness Tester complies with several key international standards to ensure reliability and consistency in testing procedures:

- ISO 9626:2016: This international standard specifies the requirements for the mechanical properties of hypodermic needles, including the bending test used to evaluate needle toughness.

- GB/T 18457: Chinese standard that also outlines the mechanical testing methods for medical needles.

These standards ensure that the NTT-01 Needle Toughness Tester provides accurate and compliant testing results that meet global requirements.

Support and Training

Cell Instruments provides comprehensive support and training services to ensure optimal usage of the NTT-01 Needle Toughness Tester. Our experts are available for:

- Installation: On-site or remote installation support.

- User Training: Tailored training programs to ensure your team can use the system efficiently.

- Technical Support: Ongoing technical assistance, including troubleshooting and maintenance, to maximize the lifespan of your tester.

- Calibration and Certification: Regular calibration services to maintain precision and compliance with industry standards.

Frequently Asked Questions (FAQ)

- What types of needles can the NTT-01 test?

- En NTT-01 is designed for testing hypodermic needles of various wall thicknesses, including regular-walled, thin-walled, and extra-thin-walled types.

- What standards does the NTT-01 comply with?

- En NTT-01 meets the requirements of ISO 9626 y GB/T 18457 for testing the bending resistance of hypodermic needles.

- How do I set the bending angle?

- The bending angle can be adjusted to 15°, 20°, or 25°, depending on the type of needle being tested.

- Can the NTT-01 simulate real-world conditions?

- Yes, the tester accurately simulates the mechanical forces needles undergo during insertion and withdrawal, ensuring realistic testing results.

- Is the NTT-01 easy to operate?

- Yes, with its HMI touchscreen interface y PLC control, the NTT-01 is designed for easy operation, requiring minimal training.